Engine break-in is not a glamorous topic, it is often overlooked, underperformed or not even considered, but it is literally the most important activity for a new propulsion system to achieve optimal performances.

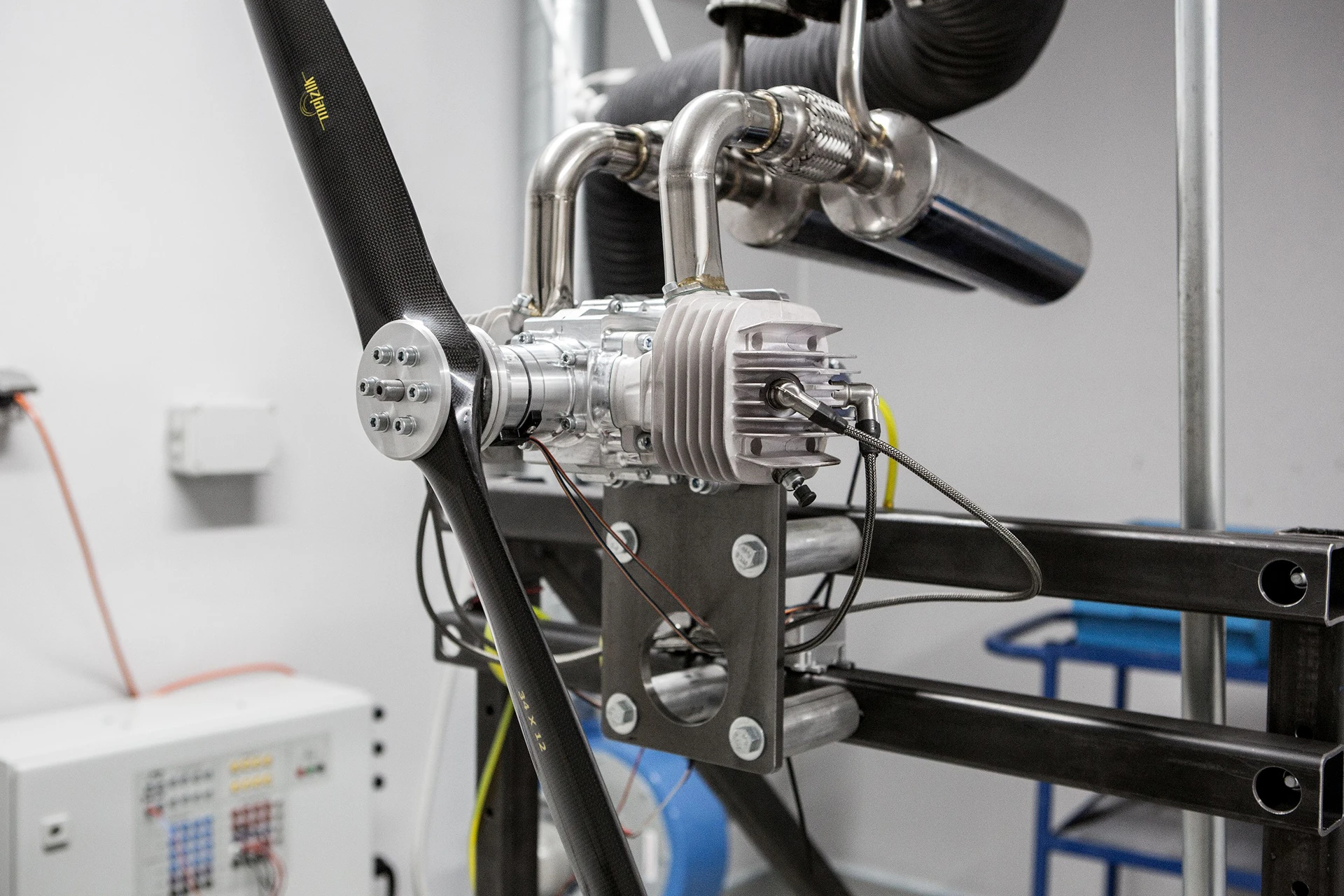

Engine break-in is a cyclical process performed over a series of hours, rather than minutes, allowing the engine’s internal parts to properly adjust to each other, especially the piston rings and cylinder walls.

Cylinder walls, despite their shiny new appearance, are not perfectly smooth, but have microscopic imperfections. Piston rings need to be broken-in to conform to these surfaces. Following the correct processes will decrease fuel consumption, optimize compression and provide the user with a more reliable combustion cycle.

Furthermore, a fully broken-in engine will achieve a higher peak RPM, and by proxy, higher thrust values when compared to one that is not. If the break-in phase is not completed, the service life and optimum performance of the engine are compromised.

Recent internal analysis revealed a difference in fuel consumption of 75g/kW/hrs between a broken-in engine and one that is not, under test conditions. This may seem insignificant but the grams add up quickly, especially if mission endurance is a key factor.

Sky Power International provides this service to the customer at a chargeable rate. This means the engine is delivered at your facilities ready to literally ‘plug and play’. Many customers choose this services as it provides a level of assurance that we, the propulsion specialist, will perform this activitywith precision, allowing you, as a UAV manufacturer to focus on what you do best – the manufacturing!